|

Submarine

The Submarine Products Company was founded in 1957 by Hugh Oswell while he was still in the English Royal Navy.

Lieutenant Commander Hugh Oswell was an English naval officer based in Portsmouth. In his free time he has worked on innovations and modifications in diving equipment and developed his own designs for diving equipment. He was aided in the production of his prototypes by Harry Biscoe, who was also based in Portsmouth, and had access to engineering facilities.

The Royal Navy introduced a program of staff cuts and Commander Oswell, through this program, saw an opportunity to create his business.

Similarly, Harry Biscoe sent to Commander Oswell requesting a reference letter for a job. Commander Oswell offered a job in his company. Harry accepted the invitation and moved to Hexham. He remains in the company to develop the projectof the production of diving equipment.

Hugh Oswell set up a small workshop at the back of his house in Acomb, near Hexham, in Northumberland.

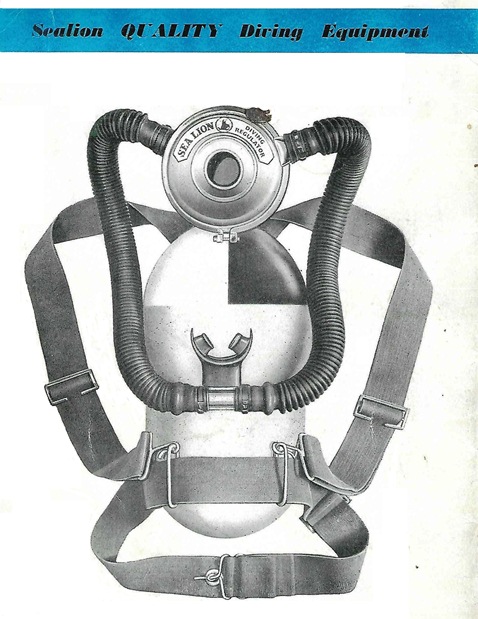

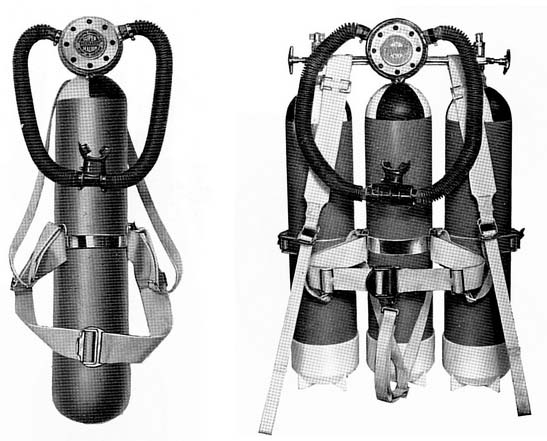

The Submarine Products Company has developed a complete line of diving equipment: valves, harness, cylinders, ballast belts, etc.

They produced the AQUAMOBILE scooter and began importing the range of other dive equipment, largely in the US, such as masks, ends, clothing and compressors.

Due to the good contacts of Hugh Oswell, the company grew up supplying

diving equipment to English Royal Navy.

In 1967 a new complete factory was built at BRIDGE END in Hexham, with test tanks for simulation of operations for the police and firefighters in the use of breathing apparatus. They also diversified the range of products made from plastic polymers. These ranged from boat hulls to plastic containers such as buckets, etc.

The company secured contracts for the supply of diving equipment to the Royal Navy and also equipped, among others, the Indian, Korean and Jordanian Navy.

From 1957 to 1980, Submarine produced five different double hose regulators: SeaLion - MK1, SeaLionMKII, Super SeaLion, Atlantic and the Black Prince.

The Submarine Products exported double hose regulators to Denmark as "SECOBA", to France as "CHAMPION" and to Germany as "TAUCHTECHICK".

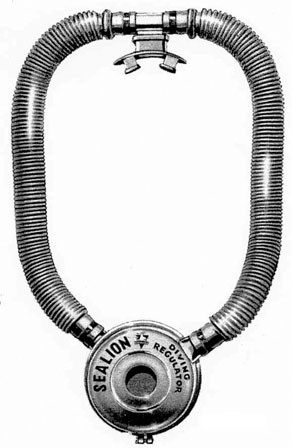

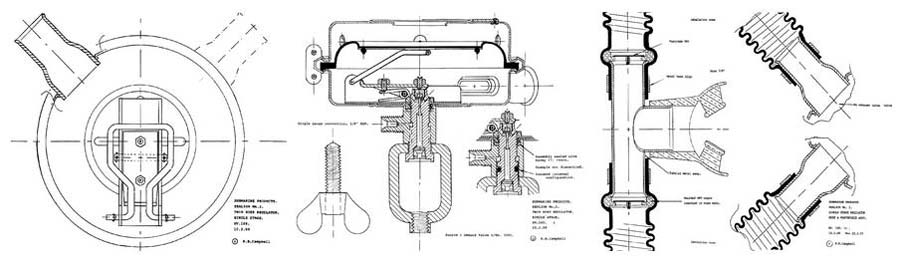

SEALION MKI

The first double hose regulator produced by Submarine was Sealion - MKI in 1957.

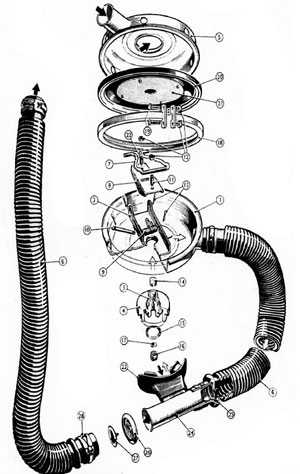

Like all models produced by the company, the Sealion MKI was a single stage regulator. With a 5 "diameter, it had the upper and lower parts fixed by a ring-type clamp. At the top of the regulator (label side) there was a central hole that allowed access to the diaphragm.

This hole allowed the diver access to the existing by-pass device under the diaphragm. When the diver needed extra air supply (in an emergency or to assist the removal water from the hoses), it was enough to actuate this device with his hands, through the existing hole.

There is no duckbill valve on the top cover of the regulator. Probably, this absence was to not generate clashes with the patent of the

Cousteau-Gagnan CG45. The mouthpiece / nozzle was of "T" type metal and the non return valves were composed of rubber discs fixed by screws and washers.

There were no gauge connection ports.

One of the characteristics of this model of regulator was the device for its fixation in the cylinder. The device was known as Captive Hand-Nut and operated with a device of the reverse DIN type. Submarine subsequently manufactured a Yoke adapter to allow SeaLions MKI to be attached to the most modern cylinder valves.

There are records that at least 500 Sealion MKI were exported to Australia through the company Walla Mitchell Pty Ltd of Melbourne.

The label was semi-circular and fixed around the hole in the top cover and contained the inscription SEALION - DIVING REGULATOR.

Sealion MKI was marketed with medical oxygen cylinders, which were war surplus. They had tappets with protruding valves "Hand-Nut" to fit into the MKI regulator.

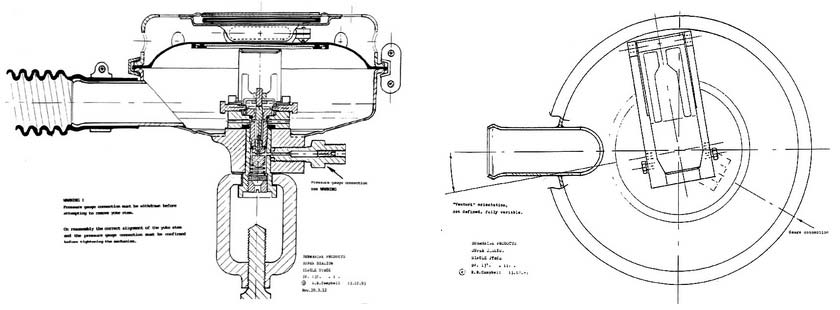

SEALION MKII

The production of this regulator occurred in the year 1958. The Submarine modified the type of fixation existing in the regulator SeaLion MKI. The Hand-Nut type system (inverted DIN) is replaced by the Yoke type fastening system.

In addition, a 1/8 "male type port was fitted for connection of a manometer. The single-stage internal mechanism is maintained, and few modifications have been made:

- The regulator filter becomes sintered bronze;

- The mouthpiece / nozzle now had non-return "mushrooms" type valves;

- The label becomes a 360 ° adhesive around the hole in the top cover and has the inscription SEA LION MKII REGULATOR - MADE IN ENGLAND - BY SUBMARINE PRODUCTS LTD. With the existence of SeaLion MKII, the SeaLion regulator becomes known as SeaLion MKI, because there was no MKI expression placed on the regulator label, or even in the bibliography.

There is still no duckbill valve on the top cover of the regulator. The metal clamps replaced the twine binding wires used in the previous model.

The cylinders used with Sealion MKII were different from those used with MKI. The cylinder valves are now Upright Pillar type, which couple to the yoke connections of the new regulators. War surplus cylinders are still used, such as the popular EX-RAF.

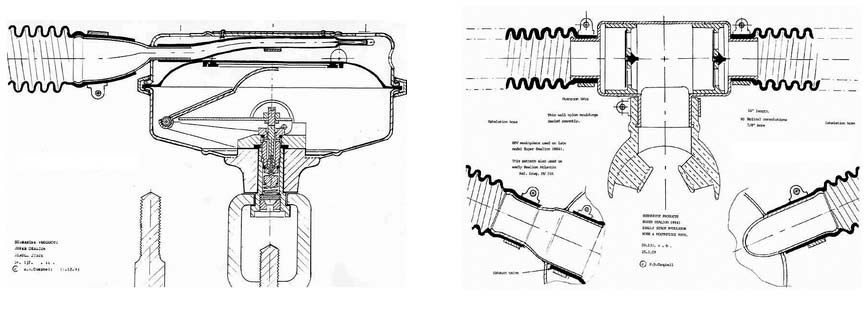

SUPER SEALION

The double hose regulator Super Sealion was produced in the period from 1959 to 1964, and was a completely redesigned model.

A metal ring still attached the top and bottom covers of the regulator, which no longer had the central hole in the top cover. Eight small holes were added in the top cover. The single-stage internal mechanism has been redesigned. The HP port for gauge connection still

remains.

The gauge connection requires care for proper coupling of the existing yoke rod with the gauge adapter.

In this model, the duckbill valve is installed in the top cover of the regulator. The duckbill was attached to the handle by a

metal strip (bridge).

The label / label was round and red in color. It had the inscription SUPER SEALION REGULATOR - SUBMARINE PRODUCTS LTD. - MADE IN ENGLAND.

A new molded plastic mouthpiece / nozzle with non-return valves is used. The hoses were secured by nylon clamps.

Os Super Sealion usavam cilindros novos fabricados pela empresa alemã IWKA.

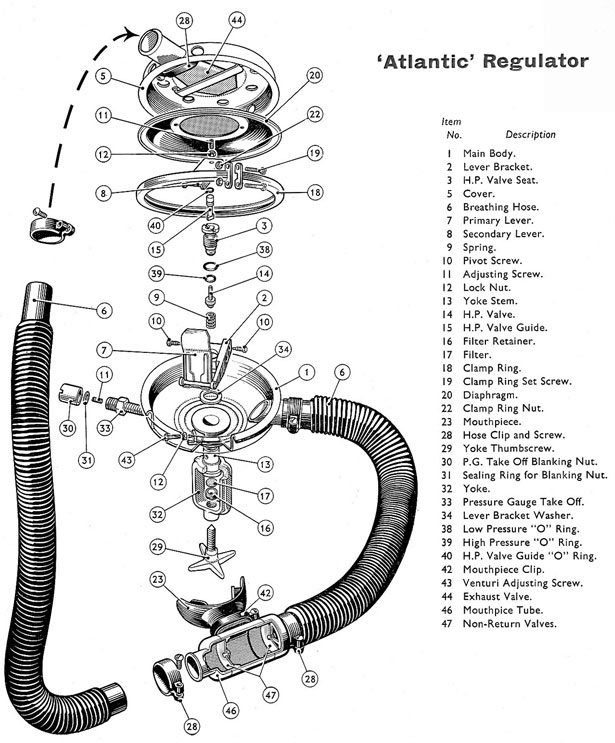

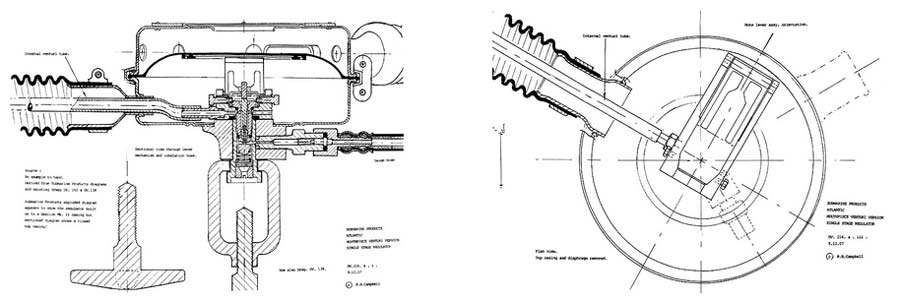

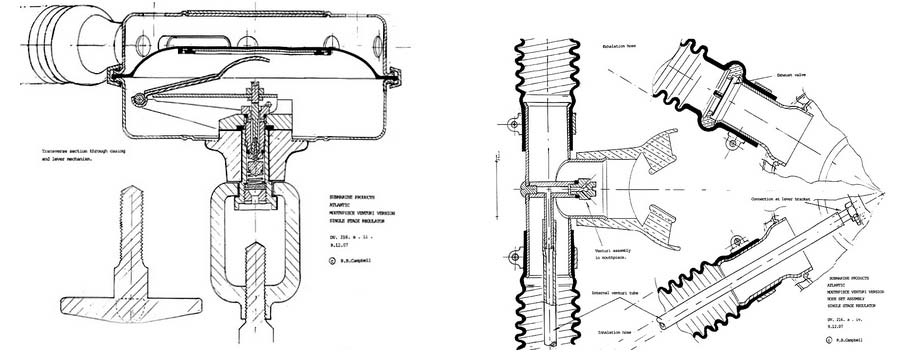

ATLANTIC

The double hose regulator Atlantic was manufactured from 1961 to 1969 and shows few differences with respect to Super Sealion.

Externally the green label was inscribed VENTURI ACTION - ATLANTIC - DIVING REGULATOR - PATENT APPLIED FOR - MADE IN ENGLAND BY - SUBMARTINE PRODUCTS LTD .. Internally, the primary lever becomes molded plastic and the secondary one remains brass.

A small modification to the HP valve pin of pressure, which now has a narrower section and allows a better flow of air through it. The mouthpiece was now of the threadable type and the hoses were secured by nylon clamps. The HP port for gauge connection remained unchanged.

There wasn't, in fact, a specific Venturi Jet as seen on other regulators with this device. What existed in the original design of the Atlantic was a small flexible plastic tube that would be placed in the inhalation hose, bringing air directly from the regulator block to the mouthpiece nozzle. This solution did not become very popular because the amount of air that was being made available to the diver was very large and, therefore, undesirable.

The Submarine quickly changed this design and returned to the old setup used in Super Sealion. It was not understood why the advertising about the Venturi Jet continued.

It is believed that there was a reuse of surplus labels for the reshaped regulators. This concept of using hoses by taking air directly from the regulator block to the mouthpiece had already been used by the US Divers a few years earlier (1955-1956) in the DX Overpressure, which survived only a year before being rejected. This makes it a mystery to why Submarine used this concept again.

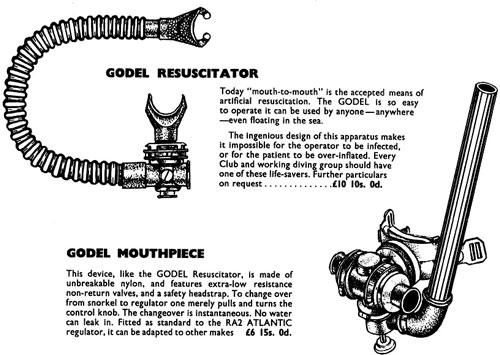

The Atlantic had the optional device known as Godel Mouthpiece (1963). Various manufacturers have used the concept of using snorkel coupled directly into the mouthpiece valve. The Submarine used this concept also. A Godel, with a bulky body and with the snorkell docked on the left side, had a valve that allowed the diver to alternate the position of the regulator for the snorkell.

The Submarine also had this device for mouth-to-mouth (Godel Resuscitator) breathing.

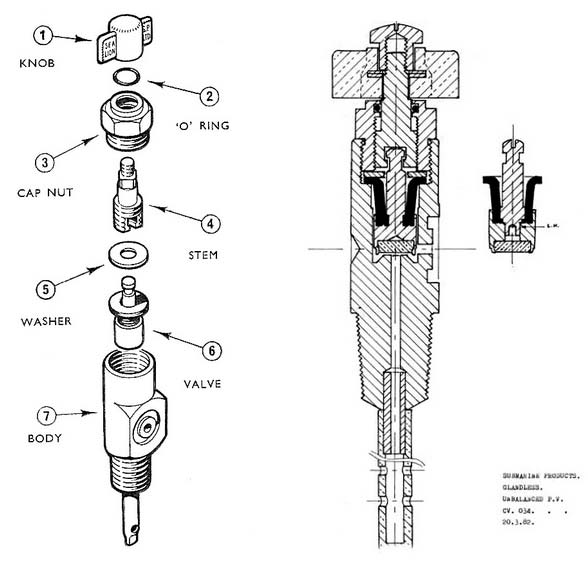

The cylinders used by the Atlantic maintained the same configuration of the previous model, but now with own valve produced by Submarine. This valve was known as "Glandless".

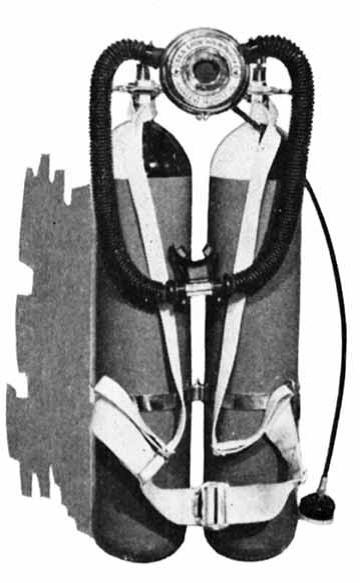

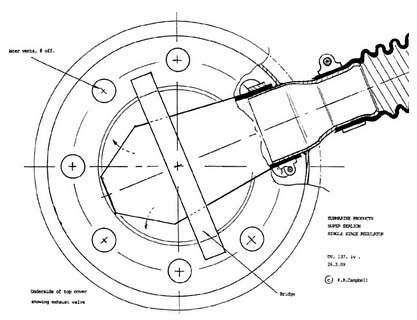

BLACK PRINCE

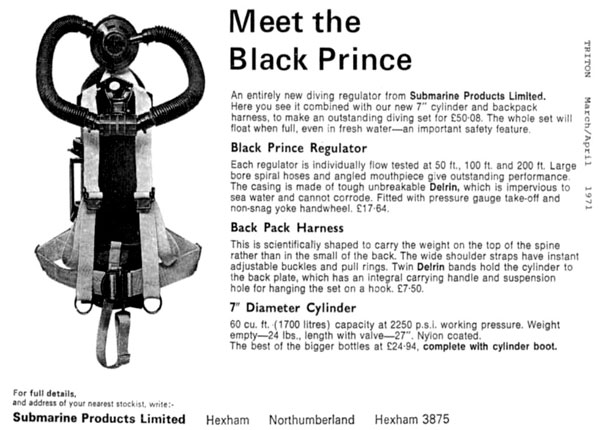

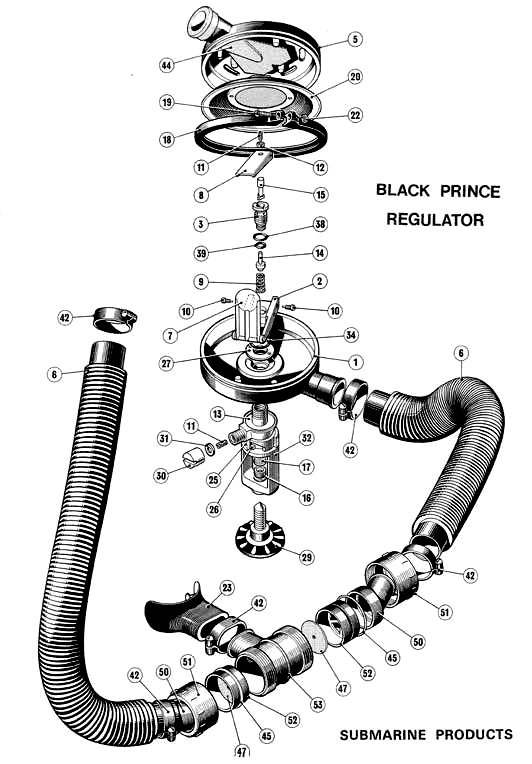

The Black Prince regulator, manufactured from 1969 to 1980, was the last double hose regulator produced by Submarine Products.

It was made in molded plastic. The two halves of the regulator were fixed by a plastic ring, just like the Atlantic. The internal design of the single-stage regulator was the same, with some minor changes:

- The primary lever now had a spoon shape;

- The exhaust valve (duckbill) was now 'wearing' the exhaust horn;

- A new yoke was drawn.

The hoses used in the Black Prince have 1 "instead of the 3/4" hoses of the other models. The mouthpiece / nozzle continues to be molded plastic (hard and threaded) but now angled for insertion of the hoses, which are secured by plastic clamps.

The Black Prince used a new aluminum cylinder produced by Luxfer instead of the IWKA steel.

The Black Prince was produced until 1980 and replaced by the single hose regulator Aquarius.

They produced a series of simple hose regulators called "Aquarius". Shortly thereafter, US Divers marketed a regulator with the same name, but withdrew from the market when threatened with a lawsuit. US Divers subsequently reintroduced this name when Submarine Products closed.

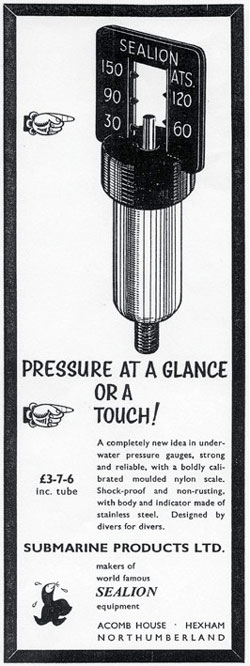

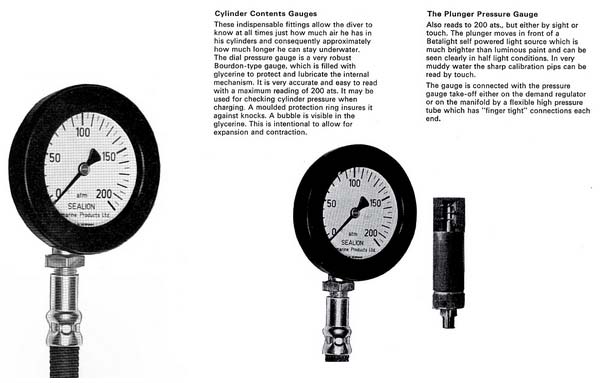

With the exception of Sealion MKI, all models of Submarine double hose regulators had a 1/8" BSP male port for manometer connection. Several types of pressure gauges were used in Submarine models:

- Plunger Gauge - It was a cylindrical metal type manometer that had an internal rod. Three models of this manometer were produced.

- Traditional pressure gauges - Produced by WIKA.

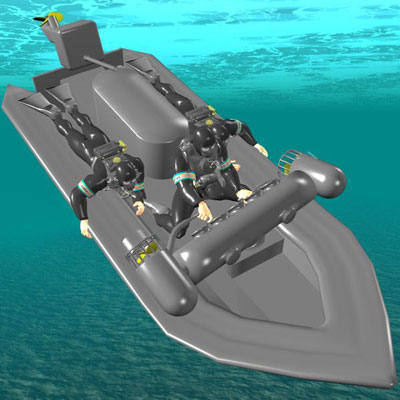

The Submarine's most ambitious project was probably the "Sub-Skimmer". It was a high speed ship on the surface, but with the ability to submerge and carry two or more divers. The cost of developing this project was phenomenal, and the company grew financially. Commander Oswell was confident that these costs would be covered by a contract with the Royal Navy, but that did not happen.

After the mid-1980s, the company was confident in renewing its twenty-year contract with the Royal Navy. However, when the contract was the bidding, the winner was the company competitor SABER AIR PRODUCTS.

The company struggled with financial problems for many years and finaly could not stand it. In June 1989, officials received the news to leave the factory and the site.

When the assets were sold, the plastics division was purchased by Mr. Ken Sayer (he had already worked for Submarine Products) and he still has the business in Alston, Cumbria, producing plastic extrusions.

The manufacture of diving equipment was purchased by Sea Sub Services of Aberdeen, under the brand name "Divex", of Aberdeen, Scotland.

Commander Hugh Oswell moved to France, where he set up a boatbuilding company. He died in 1997.

At peak production, Submarine Products Ltd. employed more than seventy people.

Reference:

(1) John Salsbury;

(2) Historical Diving Times #54 e #55- Submarine Products Twin

Hose Demand Valves by Bob Campbell;

(3) Wikipedia;

(4) Drawings - Copright de Bob Campbell - Published with his authorization

- "Copyright Historical Diving Society";

|